In industrial manufacturing, the quest for efficiency and precision drives innovation, particularly in the realm of joining and welding technologies. Among the plethora of methods available, spin welding stands out for its effectiveness, especially when dealing with thermoplastics.

This article delves into the intricacies of spin welding, highlighting its applications and advantages, and demonstrating why companies like Xfurth are leading the way in this field.

Understanding Spin Welding

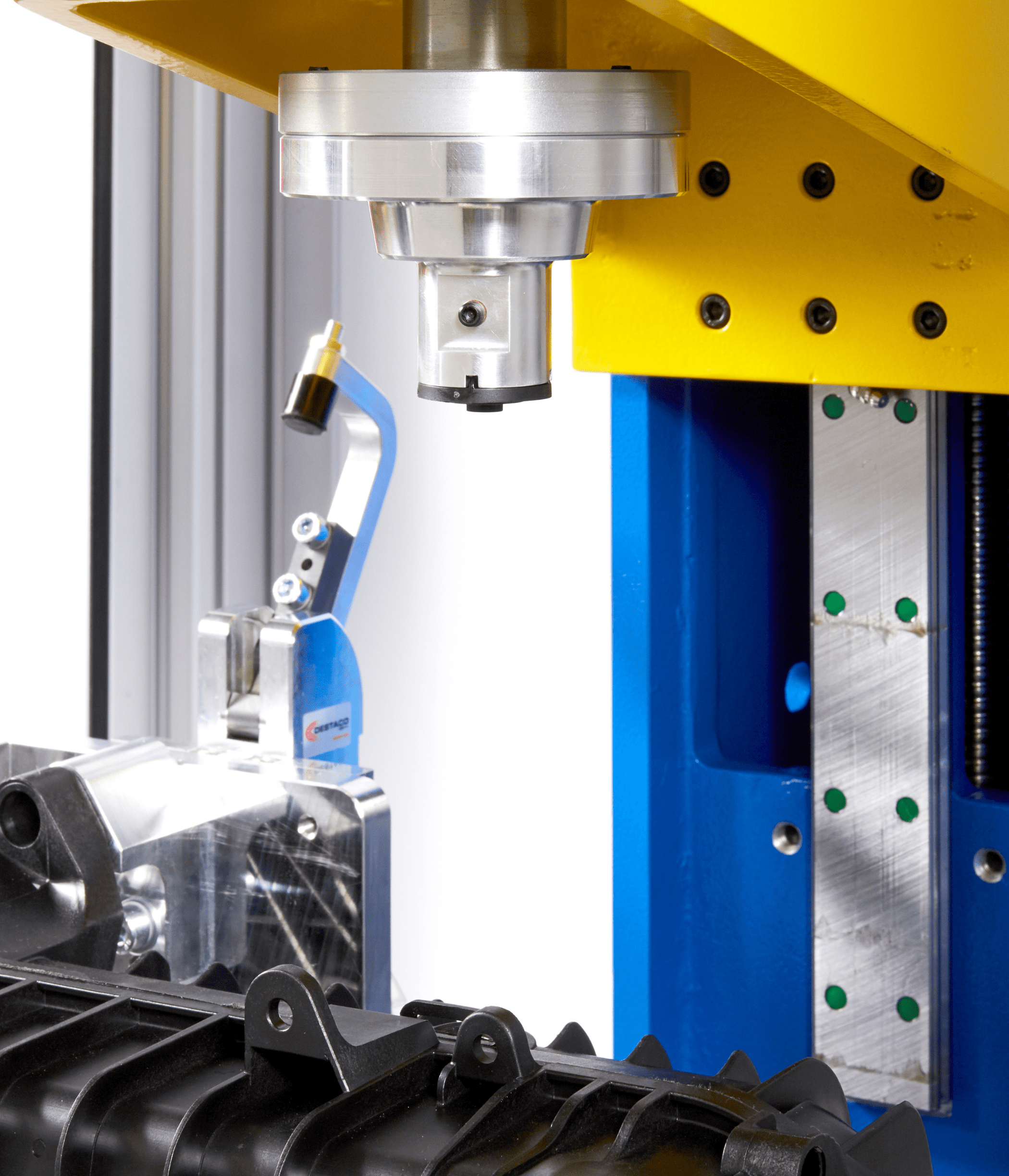

Spin welding, a method predominantly used for thermoplastic materials, employs a simple yet effective principle: frictional heat. This process involves rotating one component against another stationary piece. The friction generated between the two surfaces produces heat, which melts the plastic. When the rotation stops, the parts are held together under pressure, cooling and solidifying to create a strong, homogenous bond.

One element that should be noted is the importance of joint design. Well-considered joint design ensures that the heat generated from the process is optimally distributed across the welding interface. For instance, designing joints with an undercut can be particularly effective, especially when working with polymers of different melting temperatures. In such cases, the polymer with the lower melting point flows into the undercut during the welding process, creating a mechanical bond that enhances the strength and integrity of the joint.

Understanding this aspect of joint design is a key factor in leveraging the full potential of spin welding, allowing for strong, durable, and reliable welds in a variety of applications.

Applications By Industry

Automotive Industry

In the automotive sector, spin welding plays a crucial role in manufacturing components that demand high levels of precision and reliability. For fuel tanks, spin welding ensures leak-proof seams, a critical factor for both safety and performance. Spin welding also provides airtight connections that are essential for maintaining engine efficiency and reducing emissions.

Aerospace Sector

In the aerospace industry, the advantages of spin welding are manifold. It's used in the production of component housings, where durable and lightweight joins are vital for the functionality of sensitive equipment. It is also instrumental in the construction of cabin interiors through the welding of plastic components for seating and storage.

Consumer Electronics

For consumer electronics, spin welding is pivotal in ensuring the integrity and aesthetics of device casings. It allows for seamless joins, enhancing the product's durability while maintaining its visual appeal which is particularly important in a market where design and durability are key selling points.

Xfurth: A Cut Above The Rest

Xfurth, a pioneer in the field of plastic welding and joining systems, stands as a distinguished leader in the domain of spin welding technology, embodying a legacy of innovation and customer-focused service.

With a history that spans over three decades, their commitment to innovation and bespoke manufacturing solutions has positioned them as a premier UK manufacturer and a globally recognised brand. Xfurth's expertise, especially in providing custom solutions tailored for specific industry needs, underpins their role as a key player in the field of thermoplastic welding technologies.

Empower Your Manufacturing Processes

Spin welding has emerged as a transformative technology in the manufacturing landscape, offering precision, strength, and versatility that is a testament to the innovation and adaptability of modern manufacturing.

For those eager to explore the full potential of spin welding, we highly recommend downloading Xfurth's 'Guide To Vibration Welding', an invaluable resource, offering in-depth knowledge and guidance for industry professionals. This comprehensive resource from Xfurth offers valuable insights, tips, and best practices, empowering you to harness the benefits of spin welding and the wider applications of vibration welding into your manufacturing processes. Don't miss this opportunity to elevate your understanding and application of this cutting-edge technology.

Download your free copy now and embark on a journey of innovation with spin welding and Xfurth! Get in touch today either via our website or by giving us a call on 01582 436000!