In the dynamic world of manufacturing, precision and efficiency are paramount. Ultrasonic welding machines, a cutting-edge technology, are transforming how design engineers approach plastic welding.

XFurth, a leader in this domain, is at the forefront of providing innovative, cost-effective solutions to complex welding challenges.

What is Ultrasonic Plastic Welding?

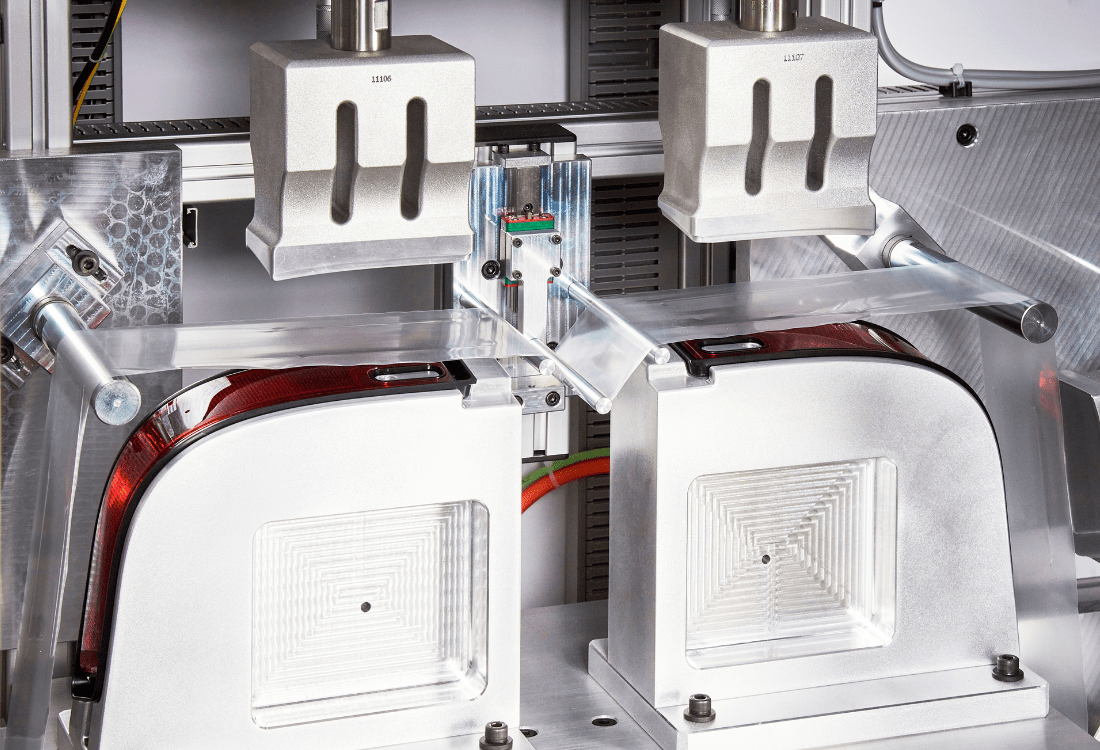

Ultrasonic plastic welding utilises high-frequency ultrasonic acoustic vibrations to create a solid-state weld at a plastic workpiece interface. This method is fast, efficient, and requires no external heat or adhesives, making it a highly sought-after solution in industries like aerospace and automotive.

Advantages Over Traditional Welding Methods

Unlike conventional welding methods, an ultrasonic welding system offers:

-

Enhanced Precision: Ultrasonic welding technology sets itself apart from traditional welding methods in its remarkable precision and unmatched accuracy, which is crucial for the assembly of intricate and delicate components.

-

Energy Efficiency: Unlike conventional welding that often relies on high energy consumption, this method reduces the overall energy footprint, aligning with modern sustainable manufacturing practices.

-

Clean and Environmentally Friendly: The technology eliminates the need for solvents or adhesives, which are common in other forms of welding. This not only reduces the emission of harmful chemicals but also promotes a cleaner and safer working environment.

Applications In Various Industries

The versatility of ultrasonic welding machines enables their application in a wide range of industries, each with its unique requirements.

- Aerospace: In the aerospace sector, the technology is used to assemble lightweight yet robust components, crucial for the performance and safety of aircraft.

- Automotive: The automotive industry, known for its demand for high-strength and durable parts, also benefits greatly from ultrasonic welding as it allows for the production of complex parts efficiently, contributing to the industry's evolving demands for innovation and strength.

- Medical Devices: Ultrasonic welding plays a critical role in ensuring the sterility and precision of critical medical equipment. The technology's ability to create strong, reliable bonds without compromising the cleanliness of the components makes it indispensable in the medical field.

XFurth: Pioneers In Plastic Welding Technology

With a rich history spanning over 30 years, XFurth has established itself as a leader in the field of plastic welding technologies. The company's expertise is not just in providing standard solutions but in employing a bespoke approach that ensures each client's unique challenges are addressed with the most effective and efficient welding solutions.

The hallmark of XFurth's service is its commitment to continual innovation. By staying at the forefront of technological advancements in plastic welding, XFurth offers its clients the latest and most effective welding solutions.

Charting A New Course In Manufacturing with Ultrasonic Welding

In the realm of modern manufacturing, ultrasonic welding machines are redefining the standards of precision and efficiency. These machines stand as testaments to the immense potential of innovation, transforming the way we approach the assembly and fabrication of plastic components.

For those keen to find out more, XFurth offers an invaluable resource: "The Guide To Ultrasonic Welding Machines & Tooling." This comprehensive guide is packed with insights, expert advice, and detailed information, making it an essential read for anyone interested in the future of manufacturing.

We warmly invite you to download this free guide from our website today and embark on a journey to discover the full potential of ultrasonic welding in revolutionising your manufacturing processes. Get in touch with our expert team today, either via our website or by giving us a call on 01582 436000.