Find out how spin welding could help your production requirements today.

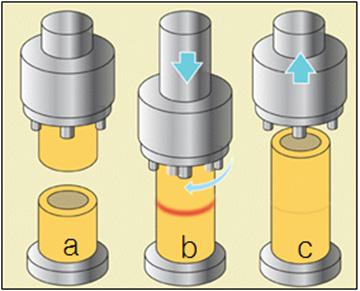

The concept of spin or rotional welding is very simple: the base component is kept static whilst the upper moulding is rotated and forced together. This action creates frictional heat that, when cooled and under carefully maintained pressure, creates a hermetic seal of exceptional strength. This occurs in only a few seconds.

The spin welding process is suitable for most thermoplastics both filled and unfilled, making it a choice joining process for manufacturers in many different industries, including:

- Automotive

- Medical

- Plumbing & Building

- Filter Manufacture

At Xfurth, our British-manufactured welding machines incorporate a fully servo-operated control, ensuring the utmost process accuracy. With a range of standard and special purpose-built spin welders available, we are able to meet the majority of our customers’ challenges. Our past projects have ranged from 6mm – 200mm diameter.

For further information, feasabilty on a project or free trial contact us today on 01582 436 000.