There are three distinct types of plastics which respond to ultrasonic welding in different ways: thermoplastics, elastomers and resins.

Elastomers & Resins

Elastomers are polymers with elastic properties, giving them the ability to recover their original shape and structure after being stretched. These materials have very low ultrasonic weldability and are not generally recommended.

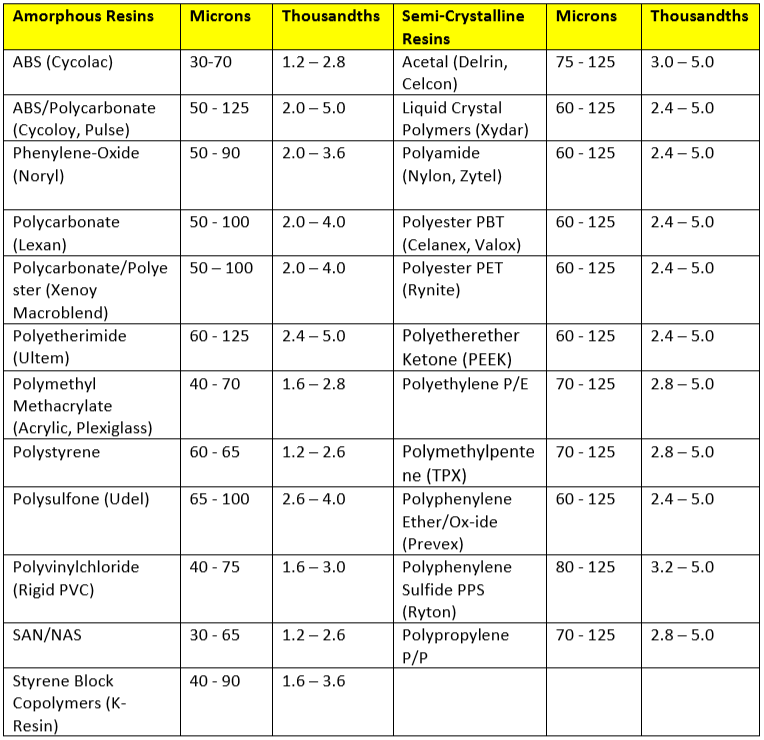

There are two types of resin classes: amorphous and crystalline. Amorphous resins, such as ABS and PMMA (acrylic), lend themselves to ultrasonic welding due to their ability to soften, melt, flow and set gradually during the heating and cooling process. Crystalline resins, with a high and narrowly defined melting point, are generally less suitable for welding and require higher energy levels for the process to be successful. Due to the way that crystalline resins react to heat, a more complex joint design is typically required. Nylon, PEEK and PC-PET are examples of crystalline resins that can be ultrasonically assembled.

Thermoplastics

A thermoplastic is a plastic polymer material that melts and becomes malleable when it is heated at certain temperatures and sets when it cools. It can be melted and set repeatedly without its molecular structure being compromised. This compares to thermoset plastics, which do not respond to ultrasonic welding because they are irreversibly set and, consequently, degrade when heated.

The suitability of a thermoplastic for welding will depend on its thermal conductivity, rigidity and elasticity. The more rigid the better, as this increases the material’s readiness to transmit vibrational energy. As a general rule, pieces made from the same thermoplastic material will weld together.

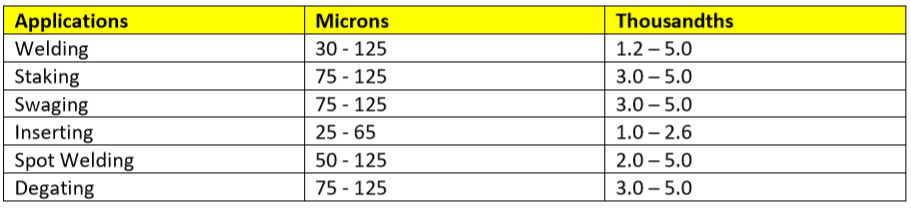

Thermoplastic 20kHz Amplitude Reference

Welding Dissimilar Plastics

The welding of two different plastics is possible, provided that their properties are compatible. For example, ABS can be assembled to weld with PMMA or PC, although appropriate preparation measures must be taken to ensure that the welding process is successful. For example, when welding terpolymers with homopolymers, the energy director should be incorporated onto the homopolymer workpiece.

Download Our Free Ultrasonic Welding Guide

Discover the benefits of ultrasonic welding in our free Ultrasonic Welding Guide. Click here to claim your copy.