Ultrasonic Insert Welding is a commonly used assembly method for inserting metal inserts into a variety of plastics, post-moulding. It can prove more reliable than traditional heat inserting methods and often more cost effective than in-mould inserting.

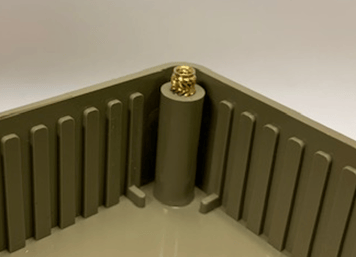

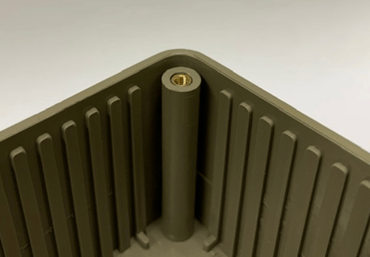

The insert pre-locates into the hole on the moulding and is driven into place via contact with the sonotrode face. To prevent a forcing effect with insufficient melt, the ultrasonics are pre-triggered with a low/medium pressure and a slow head speed. Once the insert has been welded to the correct position, the insert is allowed to cool in place, under pressure.

With the optimum insert position either flush or sub-flush to the moulding surface it is beneficial to monitor the height for complete process control and repeatability.

Typically, sonotrode/tools for inserting applications would be manufactured from hardened steel to prevent premature wear whilst contacting the inserts.

With ultrasonic insertion, it is possible to simultaneously weld multiple inserts, greatly reducing cycle time.

|

|

| Pre-welding | Post-welding |

For any further information or to see how ultrasonic insertion can benefit your assembly process, contact Xfurth today on 01582-436000 or visit www.xfurth.com.