In the pantheon of plastic manufacturing technologies, hotplate welding stands as one of the most versatile and reliable joining methods for thermoplastic components.

Hotplate Welding of Plastic Parts: A Versatile Solution For Strong, Hermetic Seals

Tags: Ultrasonic Welding

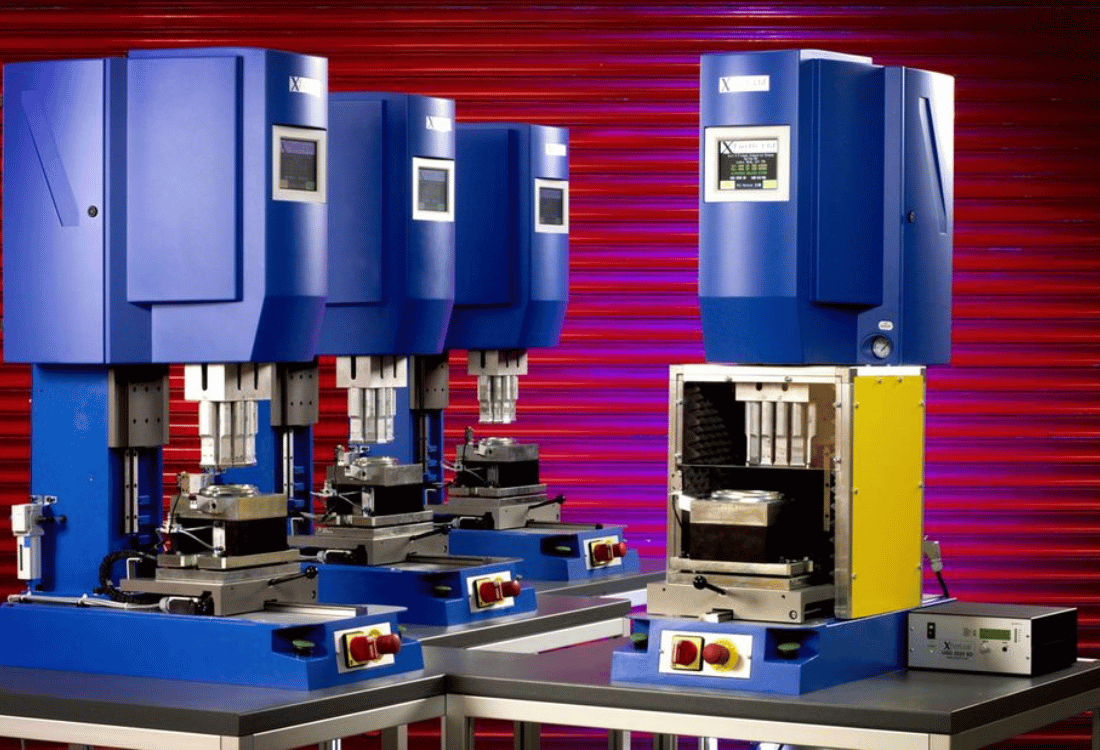

The Diverse Capabilities Of Ultrasonic Plastic Assembly

When manufacturers think of ultrasonic welding, most envision the basic joining of two thermoplastic parts. However, this perception dramatically undervalues the technology's true potential.

Tags: Plastic Welding

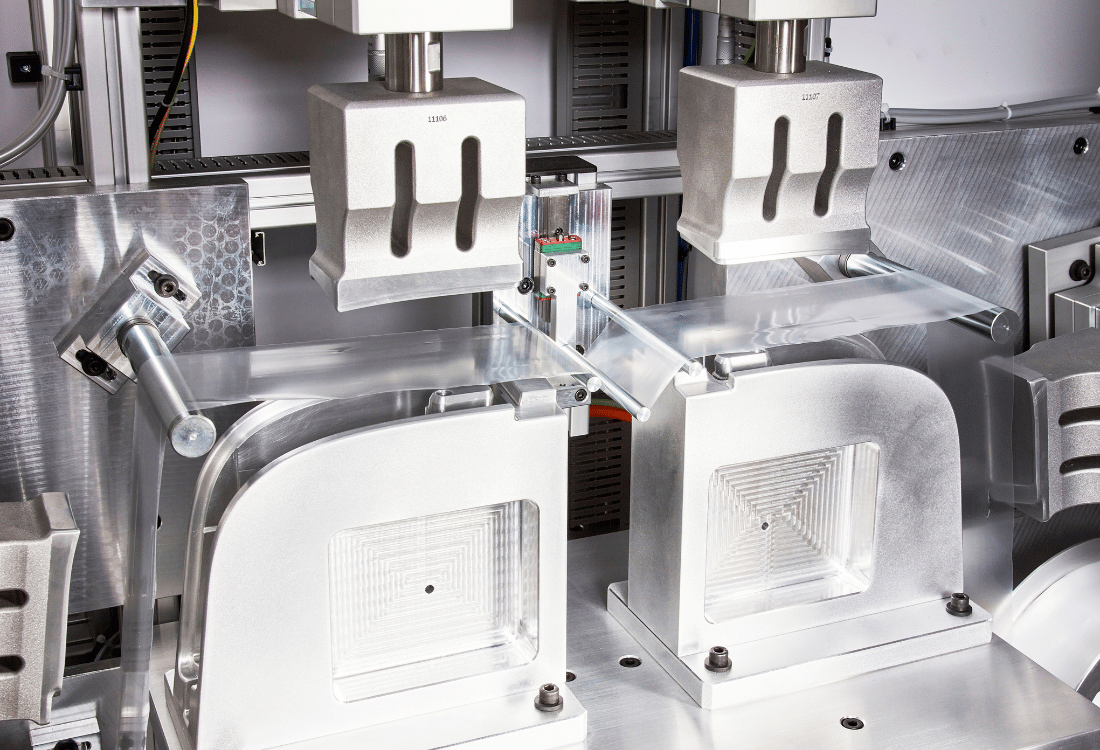

In the realm of plastic welding, the vibration welding process stands as a remarkable technique that has gained significant traction in various industries. This step-by-step guide will walk you through the essential aspects of vibration welding, providing valuable insights into its applications and advantages.

Tags: Vibration Welding

How To Optimise Ultrasonic Welding Parameters: Amplitude, Pressure, And Time

Ultrasonic welding has become an indispensable joining technology across industries ranging from automotive and medical device manufacturing to electronics and packaging. This non-thermal process uses high-frequency vibrations to create strong molecular bonds between materials—typically thermoplastics or non-ferrous metals—without adhesives, fasteners or external heat sources.

Tags: Ultrasonic Welding

Top Joint Designs For Ultrasonic Welding: Pros And Cons

Ultrasonic welding is a fast, repeatable, and precise process for joining thermoplastics without the use of adhesives, screws, or solvents. Its effectiveness hinges not just on machine parameters, but on an often-overlooked detail: joint design. The geometry and features of the joint directly impact weld strength, aesthetics, and cycle efficiency.

Tags: Ultrasonic Welding