When it comes to plastic welding, selecting the appropriate welding method is crucial to ensure optimal joint strength and integrity. Two commonly used techniques are vibration welding and ultrasonic welding. This article aims to compare and contrast these methods, providing design engineers with insights to make informed decisions about which method suits their specific application requirements. By understanding the key differences and advantages of vibration welding and ultrasonic welding, you can choose the right welding method for your plastic welding needs.

Choosing the Right Welding Method: Vibration Welding vs. Ultrasonic Welding

Tags: Vibration Welding

Selecting the right Ultrasonic Welding Machine: Key Factors

Ultrasonic welding machines are pivotal in ensuring successful ultrasonic welding processes. The selection of the right machine is crucial for achieving reliable and efficient welds. This comprehensive guide will discuss essential considerations that will help you choose the ideal ultrasonic welding machine for your specific application. Whether you are a design engineer or a manufacturing professional, understanding these factors will empower you to make informed decisions and maximise the benefits of ultrasonic welding.

Tags: Ultrasonic Welding

Step-by-Step: A Comprehensive Guide to the Ultrasonic Welding Process

Ultrasonic welding is a widely used technique for joining plastic components with precision and efficiency. This comprehensive guide will walk you through the step-by-step process of ultrasonic welding, providing valuable insights and key considerations for successful implementation. Whether you are a design engineer or a manufacturing professional, mastering the ultrasonic welding process will empower you to create strong and durable plastic assemblies

Tags: Ultrasonic Welding

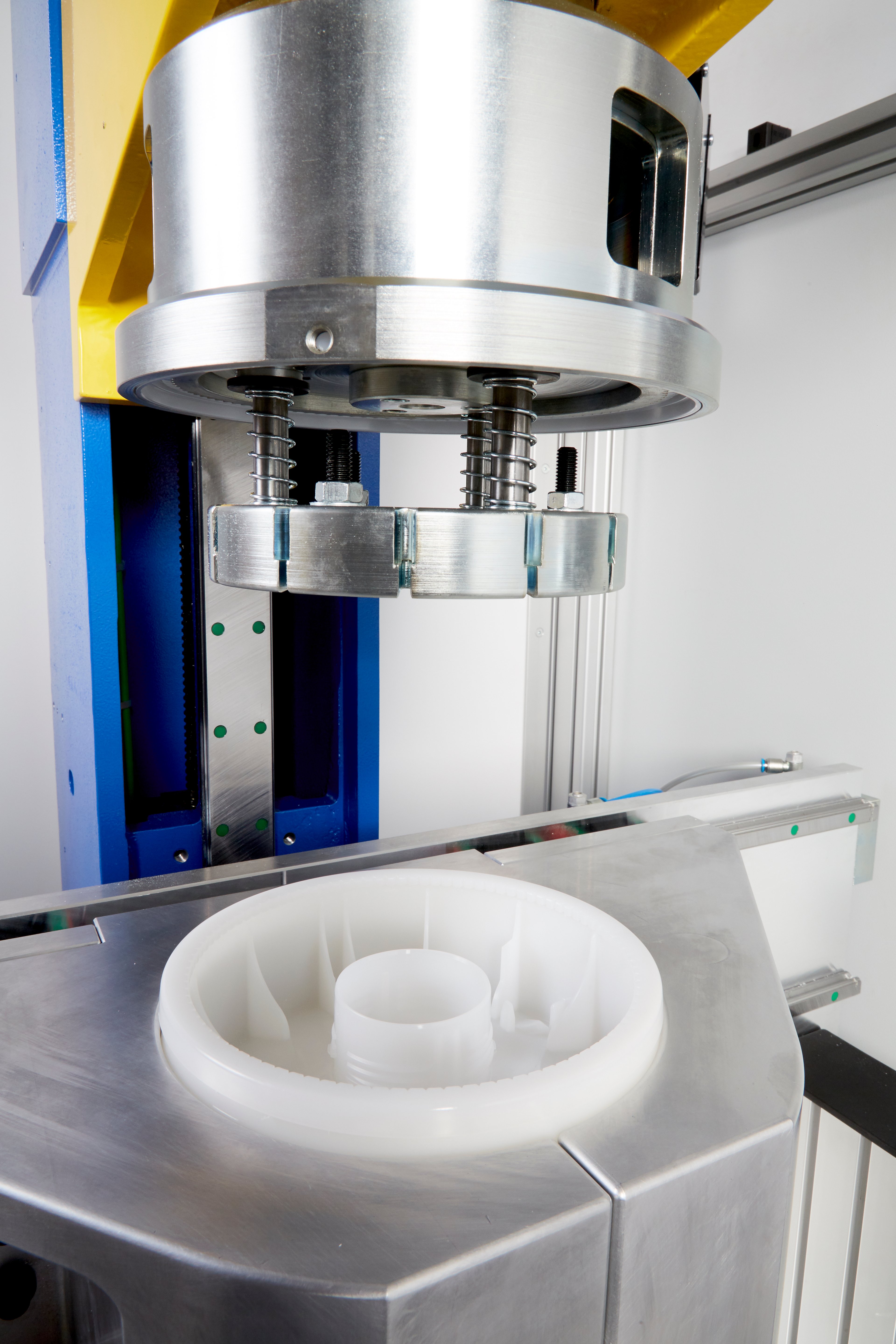

Spin Welding Demystified: A Step-by-Step Guide to the Process

Spin welding is a widely used plastic welding technique known for its reliability and efficiency in creating strong, leak-proof joints. This comprehensive guide aims to demystify the spin welding process, providing design engineers with a step-by-step understanding of achieving successful spin welds. Whether you are new to spin welding or looking to enhance your knowledge, this article will equip you with the essential information to make informed decisions and optimise your plastic welding processes.

Tags: Spin Welding

Mastering Ultrasonic Welding: Design Guidelines for Perfect Joints

Ultrasonic welding is a highly efficient technique for joining plastic components, but achieving perfect joints requires careful attention to design guidelines. In this article, we will explore the essential principles and considerations that will help you master ultrasonic welding and create flawless plastic joints.

Tags: Ultrasonic Welding