When it comes to plastic welding, selecting the right technique is crucial for achieving strong and reliable joints. Among the available options, ultrasonic welding stands out as a preferred choice for design engineers in various manufacturing sectors. In this article, we will explore the key benefits of ultrasonic welding and why it is highly regarded in the industry.

Why Choose Ultrasonic Welding? Discover 5 Key Benefits You Should Know

Tags: Ultrasonic Welding

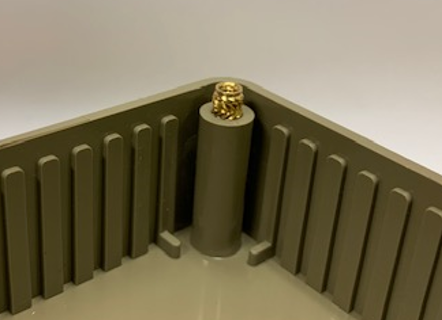

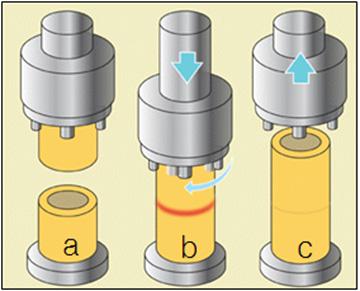

Ultrasonic Insert Welding is a commonly used assembly method for inserting metal inserts into a variety of plastics, post-moulding. It can prove more reliable than traditional heat inserting methods and often more cost effective than in-mould inserting.

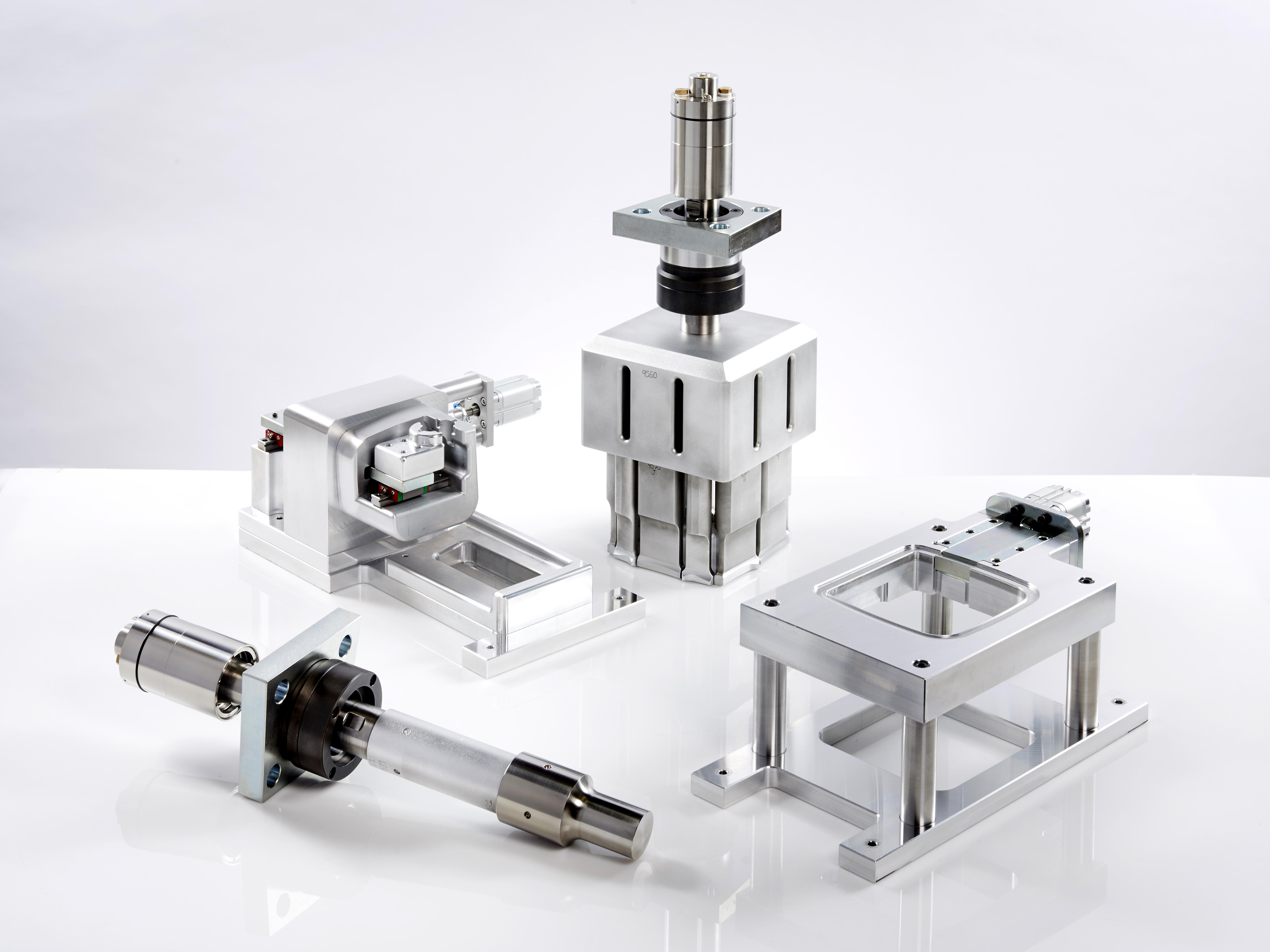

Economical, reliable and easily automated, ultrasonic welding is a popular technique in the plastics welding industry. Ultrasonic welding differs from more traditional forms of welding, where heat is generated through contact with a direct heat source.

Tags: Ultrasonic Welding

There are three distinct types of plastics which respond to ultrasonic welding in different ways: thermoplastics, elastomers and resins.

Tags: Ultrasonic Welding

Try Spin Welding! Find out how spin welding could help your production requirements today. The concept of spin or rotional welding is very simple: the base component is kept static whilst the upper moulding is rotated and forced together. This action creates frictional heat that, when cooled and under carefully maintained pressure, creates a hermetic seal of exceptional strength. This occurs in only a few seconds.

Tags: Plastic Welding, Spin Welding