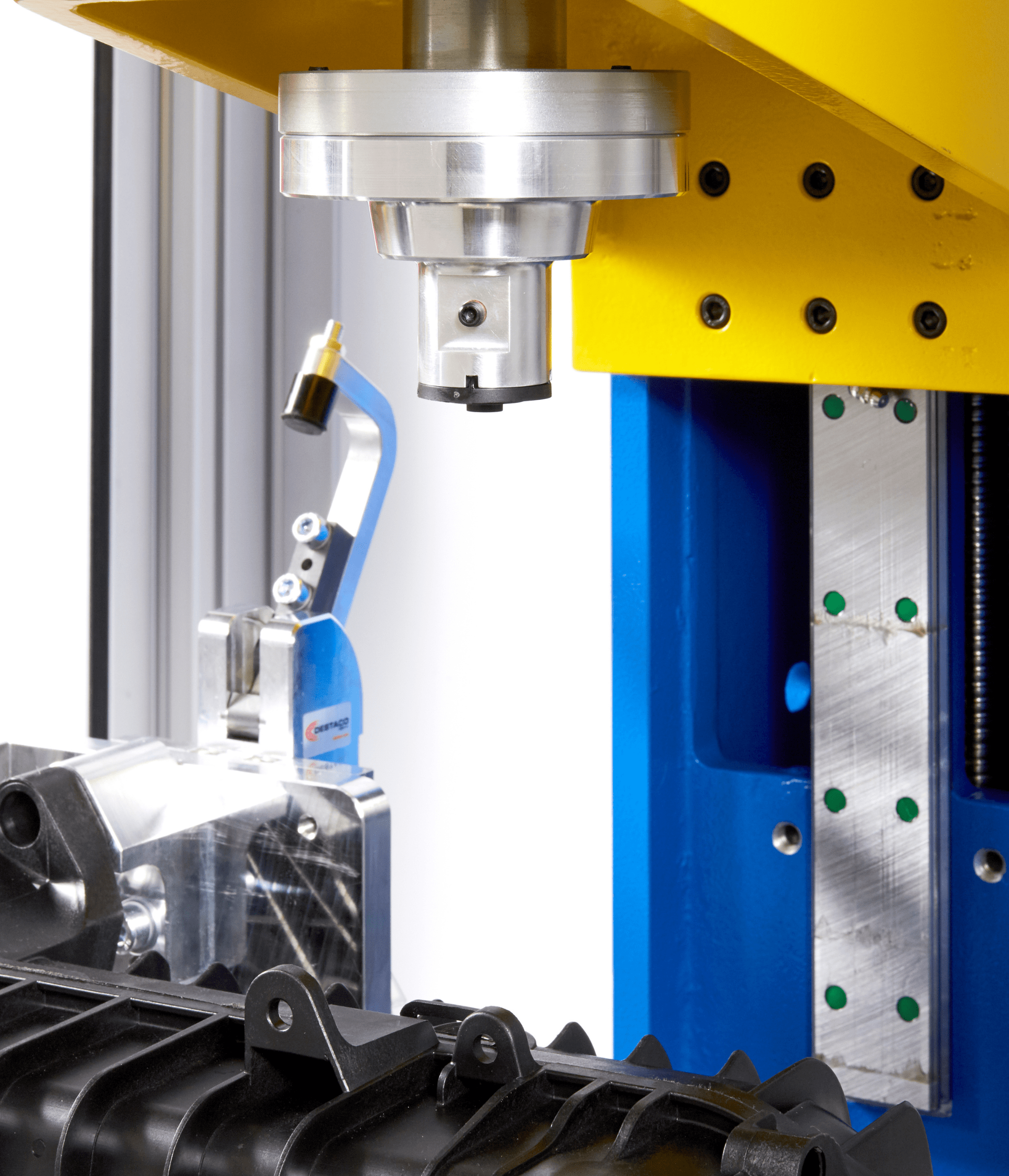

In industrial manufacturing, the quest for efficiency and precision drives innovation, particularly in the realm of joining and welding technologies. Among the plethora of methods available, spin welding stands out for its effectiveness, especially when dealing with thermoplastics.

Strength In Rotation: Industrial Applications Of Precision Spin Welding

Tags: Spin Welding

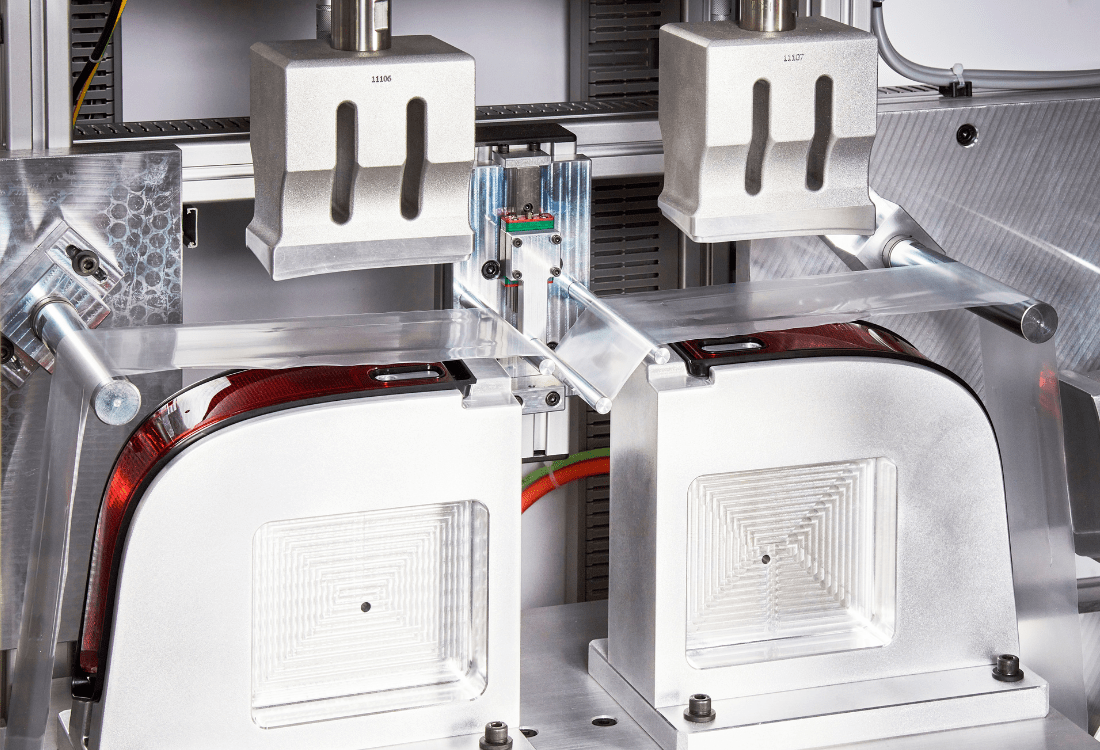

Solid Bonds, Seamless Assemblies: How Vibration Welding Transforms Industries

Vibration welding has emerged as a pivotal technology in contemporary manufacturing, fundamentally altering traditional assembly and bonding methods. This advanced process harnesses controlled mechanical vibrations to produce frictional heat, achieving a seamless fusion of parts.

Tags: Vibration Welding

Slice To Perfection: Innovations In Ultrasonic Food Cutting Technology

The food manufacturing and processing industries constantly strive for advancements that enhance precision, efficiency, and safety. A revolutionary development in this endeavour is the emergence of ultrasonic food cutting technology, an innovative approach that uses ultrasonic waves to cut food, providing numerous benefits compared to traditional cutting methods.

Tags: Ultrasonic Welding

Revolutionising Manufacturing: How Ultrasonic Welding Machines Redefine Precision

In the dynamic world of manufacturing, precision and efficiency are paramount. Ultrasonic welding machines, a cutting-edge technology, are transforming how design engineers approach plastic welding.

Choosing the Right Tools: A Guide to Ultrasonic Welding Equipment

Ultrasonic welding equipment is at the forefront of modern manufacturing, offering precision, speed, and reliability. But with a variety of options available, how do you choose the right tools for your specific needs? This comprehensive guide will navigate you through the world of ultrasonic welding equipment, ensuring you make informed decisions to enhance your manufacturing processes.

Tags: Ultrasonic Welding